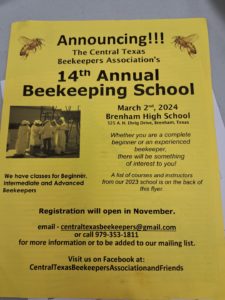

It was clear last that since we had to deliver the cedar Layens hives before the Bee School in Brenham on April 1st that we would not have a cedar hive to display at the school. We just finished up three pine hives but we have not yet started on the next three cedar hive orders and there was just no way I could get one done in time. So I went back to my langstroth box idea. We did this same thing for another bee school last summer and those hives sold very fast so it stands to reason that it should do well again.

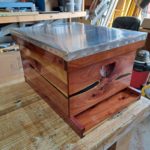

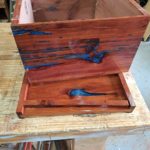

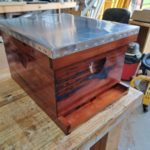

Last October I bought some cedar 1x12s and have had them finish drying for 5 months in the shop. I also had some one inch cedar slabs that were pretty poor with a lot holes but little to no rot. Last year I was playing with colored epoxy and thought, why not try on a box as well. So you see the blue epoxy hive result. This took about 5 or 6 separate epoxy fills and then let it dry and repeat. In case you did not know it takes this epoxy 24 hours to dry and about 3 days to fully cure. After planing down the epoxy boards and then sanding them with 220 the boards were nice and solid but the epoxy did not look very good. I had planned to start sanding it to a finer level but then thought I always wanted to see how a fully varnished hive would look and whether people would actually buy them. So I used Rustoleum Varnish which is supposed to have a bit more flex than standard varnish and it took three coats to get soaked into the knots. It also made the epoxy look like I put a mirror shine on it!!! Now, if only I was better at applying varnish but will need a bit more practice.

Based off the responses from the Texas Friendly Beekeepers Facebook group I think these hives and the completed unfinished cedar boxes should go fast. We should have 9 complete unfished cedar hives and two varnished epoxy hives and a few extra unfinished cedar boxes. One day I will catch up on orders I just might put a few on Etsy because shipping for a smaller 10 frame box is much easier for people to swallow than a big long lang!