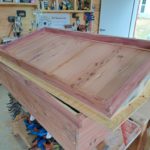

Started a new cedar hive in December and almost done with it now. The goal was to create a fully cedar hive so the bees are only touching cedar. It had a lot of spots that needed to be filled and used colored epoxy. This process is quite time consuming because the epoxy needs 24 hours to fully cure. Also had to join one of the boards which is normal for 2×12 cedar…not a lot of that running around. Once the box was created then had to route out the bottom groove and the frame rests then joined cedar boards to create the bottom.

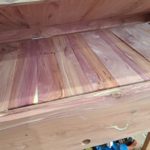

We use one inch of foam insulation in the lids and it is covered on both sides so the bees can never touch the foam…otherwise, they will chew it…it is what bees do! Was pretty happy with the inner lining of the lid and how the cedar came out.

Was planning to experiment with the roof material but locating western cedar shingles is difficult and expensive! I would certainly cover the roof in eastern cedar but it might be cedar overload. Plus I have never heard of eastern cedar on a roof and would rather experiment with my OWN hive rather than a customer build. This one will get aluminum sheeting.

Lastly the legs are the wider stance legs. I had a bit of 8/4 cedar left and it was enough to get some nice pieces without much epoxy fill. After routing the edges and sanding, I applied epoxy to the bottoms of the legs.

Still To Do: Aluminum roof, assemble the leg stand, and add our logo to the lid.